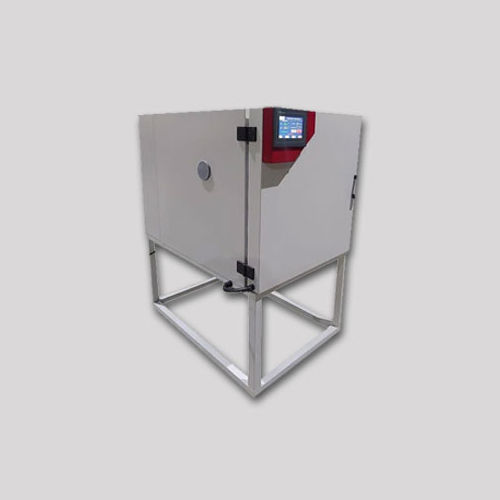

pcb curing oven

Price 700000 INR/ Number

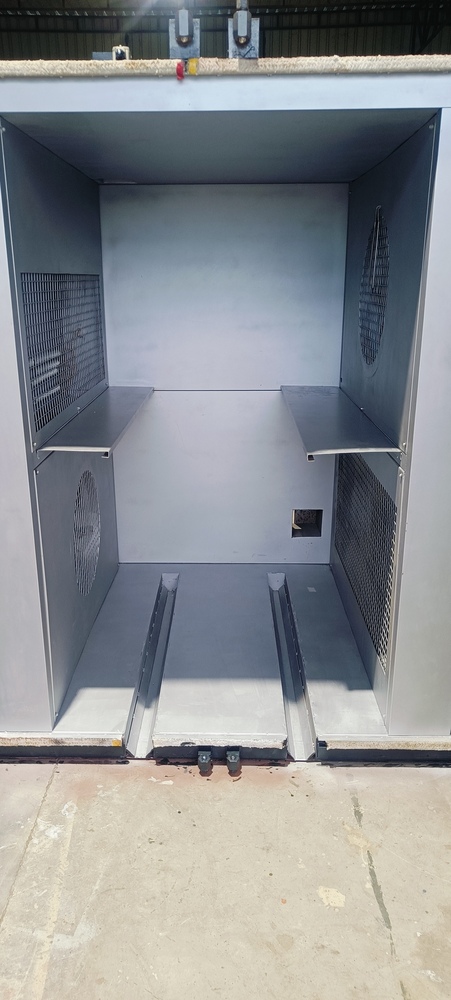

pcb curing oven Specification

- Control Mode

- Digital Temperature Controller

- Power Source

- Electric

- Accuracy

- 1C

- Condition

- New

- Heating Capacity

- 4.5 kW

- Heating Method

- Forced Air Circulation

- Type

- Batch Type Oven

- Model

- PCB-CO-800

- Internal Size

- 800 mm x 600 mm x 800 mm

- External Size

- 1050 mm x 850 mm x 1350 mm

- Volume

- Approx. 384 Litres

- Air Flow

- Horizontal, Uniform Air Flow

- Temperature Range

- Ambient to 250C

- Material

- Stainless Steel (Interior) / Mild Steel (Exterior)

- Dimension (L*W*H)

- 1050 mm x 850 mm x 1350 mm

- Power

- 4.5 kW

- Voltage

- 230V AC, Single Phase

- Surface Finish

- Powder Coated

- Timer Range

- 0-999 minutes Digital Timer

- Noise Level

- <65 dB

- Insulation Thickness

- 75 mm Mineral Wool

- Application

- Suitable for PCB Solder Mask Curing, Resin Bonding, Component Drying, etc.

- Tray Capacity

- 3-5 Trays

- Weight

- Approx. 180 kg

- Mobility

- Heavy Duty Caster Wheels

- Preheat Time

- 15-20 mins to 150°C

- Safety Features

- Overtemperature Protection, Auto Cut-Off

- Viewing Window

- Double Layer Tempered Glass

- Door Type

- Single Front Hinged Door with Silicone Gasket

About pcb curing oven

A PCB Curing Oven is an essential piece of equipment used in the electronics manufacturing process, specifically for the curing of printed circuit boards (PCBs). These ovens are designed to heat PCBs at precise temperatures and times to ensure the optimal curing of solder pastes, adhesives, or coatings that are applied during PCB assembly.

Key Features:

-

Temperature Control:

- The oven allows precise temperature control, ensuring that PCBs are cured at the correct temperatures required for different materials. Temperature accuracy is crucial for preventing damage to sensitive components on the PCB.

-

Uniform Heating:

- The curing oven is engineered to provide uniform heat distribution, ensuring that all parts of the PCB receive consistent exposure to heat. This prevents issues like uneven curing, which can affect the performance and reliability of the final product.

-

Adjustable Time and Temperature Settings:

- Users can adjust the time and temperature settings based on the requirements of the specific solder paste or adhesive used. This versatility makes it suitable for a range of PCB types and curing processes.

-

Energy Efficiency:

- Modern PCB curing ovens are designed to be energy-efficient, minimizing power consumption while maintaining optimal curing conditions.

-

Convection or Infrared Heating:

- These ovens can utilize either convection heating (where hot air circulates around the PCBs) or infrared heating (using infrared light to heat the PCBs directly). Each method has its advantages, with convection being ideal for large batches, and infrared providing quicker, localized heating.

-

Compact and Modular Design:

- Available in various sizes, from small tabletop models to larger industrial-scale ovens. Many have modular designs that allow for easy integration into automated PCB production lines.

-

Safety Features:

- The ovens are equipped with safety features such as automatic temperature shut-off, overheat protection, and insulated walls to protect users from burns or other hazards.

Applications:

- Solder Paste Reflow: Curing or reflowing solder paste during PCB assembly.

- Adhesive Curing: Curing adhesives used for components like capacitors, resistors, and connectors.

- Conformal Coating Curing: Curing protective coatings applied to PCBs to shield them from moisture, dust, and other environmental factors.

Benefits:

- Improved PCB Quality: Ensures uniform and efficient curing, enhancing the overall quality and performance of the PCB.

- Higher Throughput: Capable of handling large volumes of PCBs, making it ideal for mass production environments.

- Durability and Longevity: Designed for continuous operation in industrial settings, offering long-term reliability.

A PCB curing oven is a crucial investment for PCB manufacturers, providing efficient and precise curing to ensure high-quality electronic products.

Superior Heat Retention and Safety

With 75 mm thick mineral wool insulation and a single front-hinged door lined with a silicone gasket, the PCB-CO-800 oven is engineered to minimize heat loss and ensure safe operation. Its overtemperature protection, auto cut-off, and digital timer enable hassle-free, controlled curing or drying, protecting both users and PCB products.

Precision and Consistent Performance

Equipped with a digital temperature controller and uniform horizontal air flow, the PCB-CO-800 maintains precise heating (1C accuracy). The forced air circulation ensures even temperature distribution across all trays, guaranteeing consistent results for solder mask curing, resin bonding, or component drying applications.

Designed for Efficiency and Usability

Preheating to 150C within 15-20 minutes, this oven accommodates 3-5 trays and fits large batches thanks to its 384-litre internal volume. Its heavy-duty caster wheels facilitate mobility, while the low noise level (<65 dB) and double-layer tempered glass viewing window promote an efficient, user-friendly experience.

FAQ's of pcb curing oven:

Q: How does the PCB-CO-800 ensure uniform curing or drying of PCBs?

A: The oven utilizes forced air circulation with horizontal air flow to distribute heat evenly across the chamber, ensuring that all tray levels receive consistent temperature. This uniformity is vital for reliable curing and drying results.Q: What safety features are included in this curing oven?

A: The PCB-CO-800 is equipped with overtemperature protection, an auto cut-off system, and a secure front-hinged door with a silicone gasket. These features work together to prevent accidental overheating and ensure user safety.Q: When can I use the oven after powering it on?

A: The oven preheats to a standard working temperature of 150C within 15-20 minutes. Once it reaches the desired temperature, it is ready for immediate use.Q: Where can this oven be effectively utilized?

A: This model is suitable for electronics manufacturing facilities, research labs, and PCB assembly lines across India. It serves applications such as PCB solder mask curing, resin bonding, and drying of components.Q: What is the process for controlling the temperature and time settings?

A: The oven features a digital temperature controller and a programmable timer (0-999 minutes). Users simply set the desired temperature and timer, and the oven maintains those parameters automatically.Q: How does the viewing window enhance operational safety and convenience?

A: The double layer tempered glass window allows users to monitor the curing or drying process without opening the door. This not only maintains internal temperature but also increases operator safety by reducing exposure risks.Q: What are the key benefits of using the PCB-CO-800?

A: This oven offers precise temperature control, uniform heating, fast preheat times, robust safety features, and user-friendly operation-all of which contribute to reliable results, improved workflow, and a safer working environment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Oven Category

PLC Lab Oven

Price 350000.0 INR / Unit

Minimum Order Quantity : 10 Units

Power Source : Electric

Condition : New

Material : Stainless Steel

Surface Finish : Galvanized

Electric Industrial Oven

Price 1100000 INR / Unit

Minimum Order Quantity : 10 Units

Power Source : Electric

Condition : New

Material : Stainless Steel

Surface Finish : Galvanized

Digital Lab Oven

Price 400000 INR / Unit

Minimum Order Quantity : 10 Units

Power Source : Electric

Condition : New

Material : Stainless Steel

Surface Finish : Galvanized

Heating Oven

Price 1100000 INR / Unit

Minimum Order Quantity : 10 Units

Power Source : Electric

Condition : New

Material : Stainless Steel

Surface Finish : Galvanized

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS