|

|

|

|

|

|

|

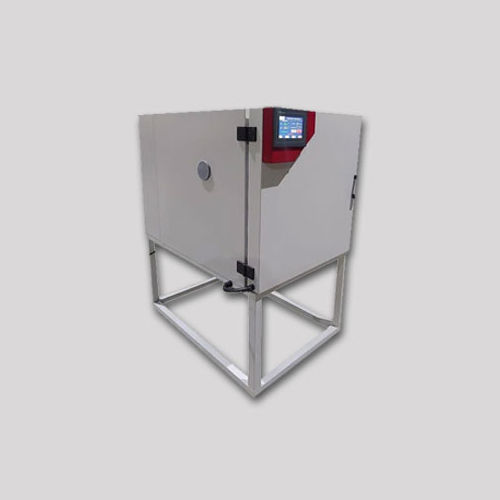

Digital Lab Oven

|

| 02

|

| Digital Lab Oven is a piece of scientific equipment that is utilized for laboratory testing and scientific research purposes. It works by using digital controls to regulate temperature and can be programmed to maintain specific temperature and duration. These ovens are typically designed with high-quality insulation and high-temperature tolerance materials to ensure uniform heat distribution and prevent heat loss. Digital lab ovens are commonly utilized in material sciences, biology, chemistry, and geology research, among other fields. Moreover, this oven can be used for a variety of purposes, such as sample preparation, drying, curing, and sterilization. They offer accurate and precise heating and temperature control, allowing scientists to carry out their experiments with confidence and consistency.

|

| Unit of Price : Unit/Units |

| Price : 400000 INR |

|

|

[Select]

|

|

|

|

Electric Industrial Oven

|

| 05

|

| Electric Industrial Oven is a device used for baking, heating, or drying materials or products, usually in large quantities. This oven is commonly used in industrial settings such as factories, laboratories, or commercial bakeries. They are powered by electricity and can be designed for a variety of applications, including batch processing, continuous operations, and custom configurations. Moreover, this oven can be used to process a wide range of products, including food items, textiles, plastic components, and metal parts. These ovens can offer significant benefits to businesses, including improved efficiency, increased output, and reduced labor costs compared to traditional manual methods.

|

| Unit of Price : Unit/Units |

| Price : 1100000 INR |

|

|

[Select]

|

|

|

|

pcb curing oven

|

| 01

|

| A PCB Curing Oven is an essential piece of equipment used in the electronics manufacturing process, specifically for the curing of printed circuit boards (PCBs). These ovens are designed to heat PCBs at precise temperatures and times to ensure the optimal curing of solder pastes, adhesives, or coatings that are applied during PCB assembly.

Key Features:

Temperature Control:

The oven allows precise temperature control, ensuring that PCBs are cured at the correct temperatures required for different materials. Temperature accuracy is crucial for preventing damage to sensitive components on the PCB.

Uniform Heating:

The curing oven is engineered to provide uniform heat distribution, ensuring that all parts of the PCB receive consistent exposure to heat. This prevents issues like uneven curing, which can affect the performance and reliability of the final product.

Adjustable Time and Temperature Settings:

Users can adjust the time and temperature settings based on the requirements of the specific solder paste or adhesive used. This versatility makes it suitable for a range of PCB types and curing processes.

Energy Efficiency:

Modern PCB curing ovens are designed to be energy-efficient, minimizing power consumption while maintaining optimal curing conditions.

Convection or Infrared Heating:

These ovens can utilize either convection heating (where hot air circulates around the PCBs) or infrared heating (using infrared light to heat the PCBs directly). Each method has its advantages, with convection being ideal for large batches, and infrared providing quicker, localized heating.

Compact and Modular Design:

Available in various sizes, from small tabletop models to larger industrial-scale ovens. Many have modular designs that allow for easy integration into automated PCB production lines.

Safety Features:

The ovens are equipped with safety features such as automatic temperature shut-off, overheat protection, and insulated walls to protect users from burns or other hazards.

Applications:

Solder Paste Reflow: Curing or reflowing solder paste during PCB assembly.

Adhesive Curing: Curing adhesives used for components like capacitors, resistors, and connectors.

Conformal Coating Curing: Curing protective coatings applied to PCBs to shield them from moisture, dust, and other environmental factors.

Benefits:

Improved PCB Quality: Ensures uniform and efficient curing, enhancing the overall quality and performance of the PCB.

Higher Throughput: Capable of handling large volumes of PCBs, making it ideal for mass production environments.

Durability and Longevity: Designed for continuous operation in industrial settings, offering long-term reliability.

A PCB curing oven is a crucial investment for PCB manufacturers, providing efficient and precise curing to ensure high-quality electronic products.

|

| Unit of Price : Number |

| Price : 700000 INR |

|

|

[Select]

|

|

|

|

PLC Lab Oven

|

| 01

|

| PLC Lab Oven is an intelligent oven that uses Programmable Logic Controllers (PLCs) to control its temperature, humidity, and other parameters. This oven is specifically designed for laboratory use, as it can maintain a precise and stable temperature range, which is essential for carrying out scientific experiments, testing materials, and conducting other research activities. PLC Lab Oven is equipped with advanced features such as timers, alarms, and automatic temperature adjustments, which enhance its usability and accuracy. Apart from that, this oven is also energy-efficient, as it optimizes its power usage based on the programmed parameters, thereby reducing operating costs.

|

| Unit of Price : Unit/Units |

| Price : 350000.0 INR |

|

|

[Select]

|

|

|

|

|

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free